The Bottle Collective

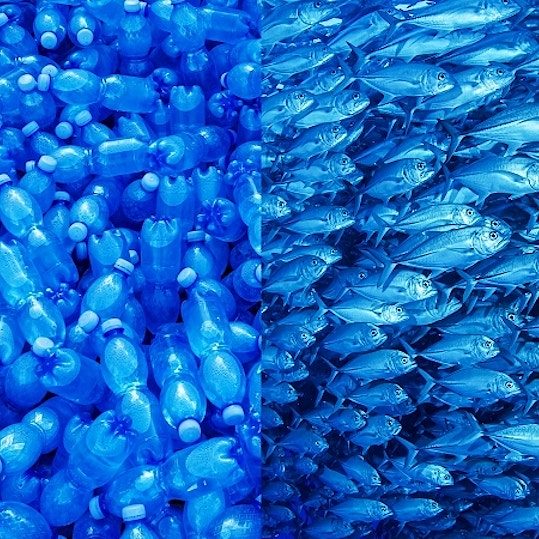

Creating the world’s first Dry Molded Fibre bottle

The Bottle Collective from PA and PulPac has joined forces with leading brand partners to create the world’s first Dry Molded Fibre bottle.

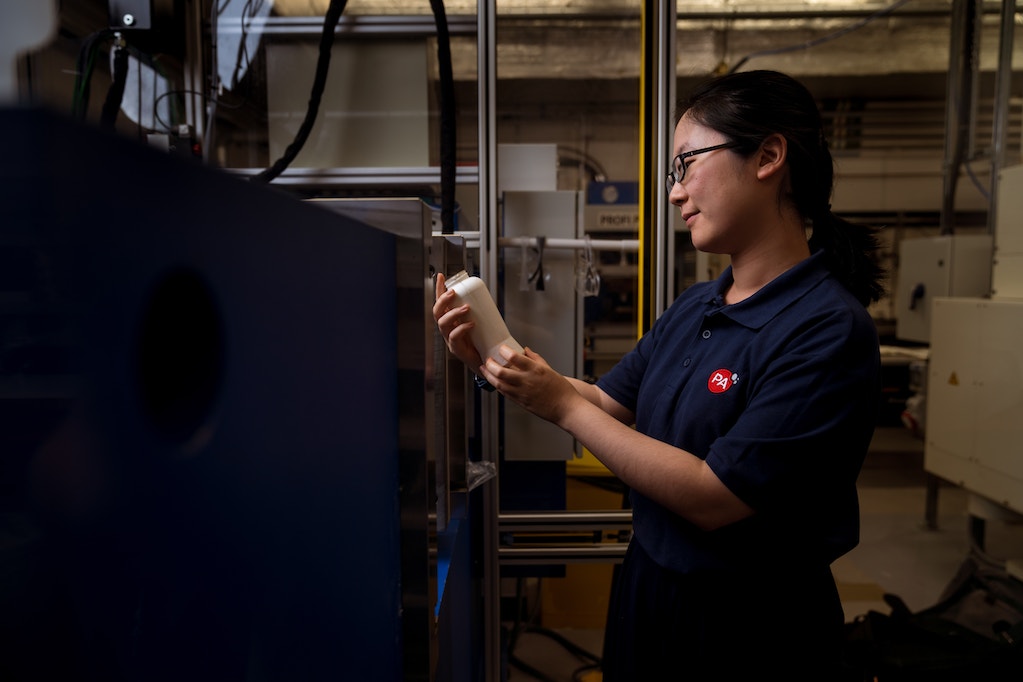

PA and PulPac have seeded the Collective and developed the underlying technology needed to bring a functioning DMF bottle to life. We have now produced the first bottle prototypes and have recruited partners to continue the development with a view to release the bottles at scale by 2025.

The technology

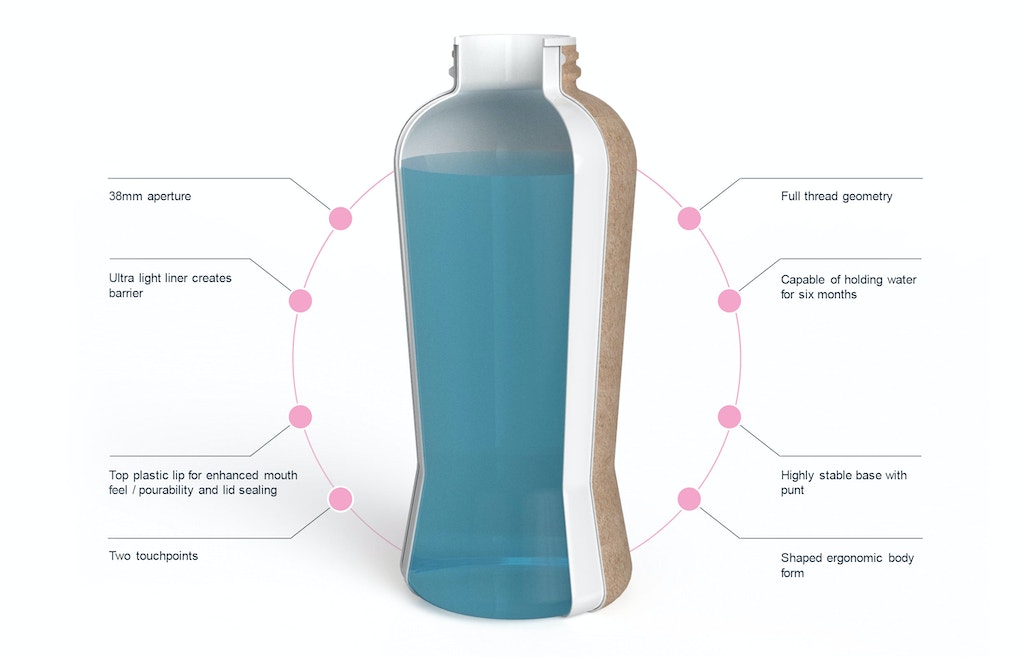

The Bottle Collective utilises Dry Molded Fibre (DMF) technology to develop bottles that minimise the use of plastics in food, drink, consumer health, and FMCG industries.

DMF technology reduces the use of energy and water compared to other production methods, creating a bottle with a significantly reduced environmental footprint. The process is designed to match the high-speed and low-cost production of plastic and uses a proprietary process to create customisable bottles that meet specific product requirements.

Technical specifications

Sustainability benefits of DMF

- Uses 1/3rd of water vs wet molded pulp

- Obtains raw material from a renewable source, with the potential to use waste stream materials as input material

- Requires no energy for drying and creates no wastewater

- Lower CO2 vs wet pulp process or other materials e.g., glass, metal, or plastic

- Low manufacturing waste due to reuse of fibres

End of Life

- Recyclable in the paper waste stream

- Higher quality pulp recyclate because of plastic liner

- Positive fibre quality and yield in recyclability studies

- Waste fibres recycled back through process

- Meets increasing global regulatory requirements

Our partners

Explore more